Product Description

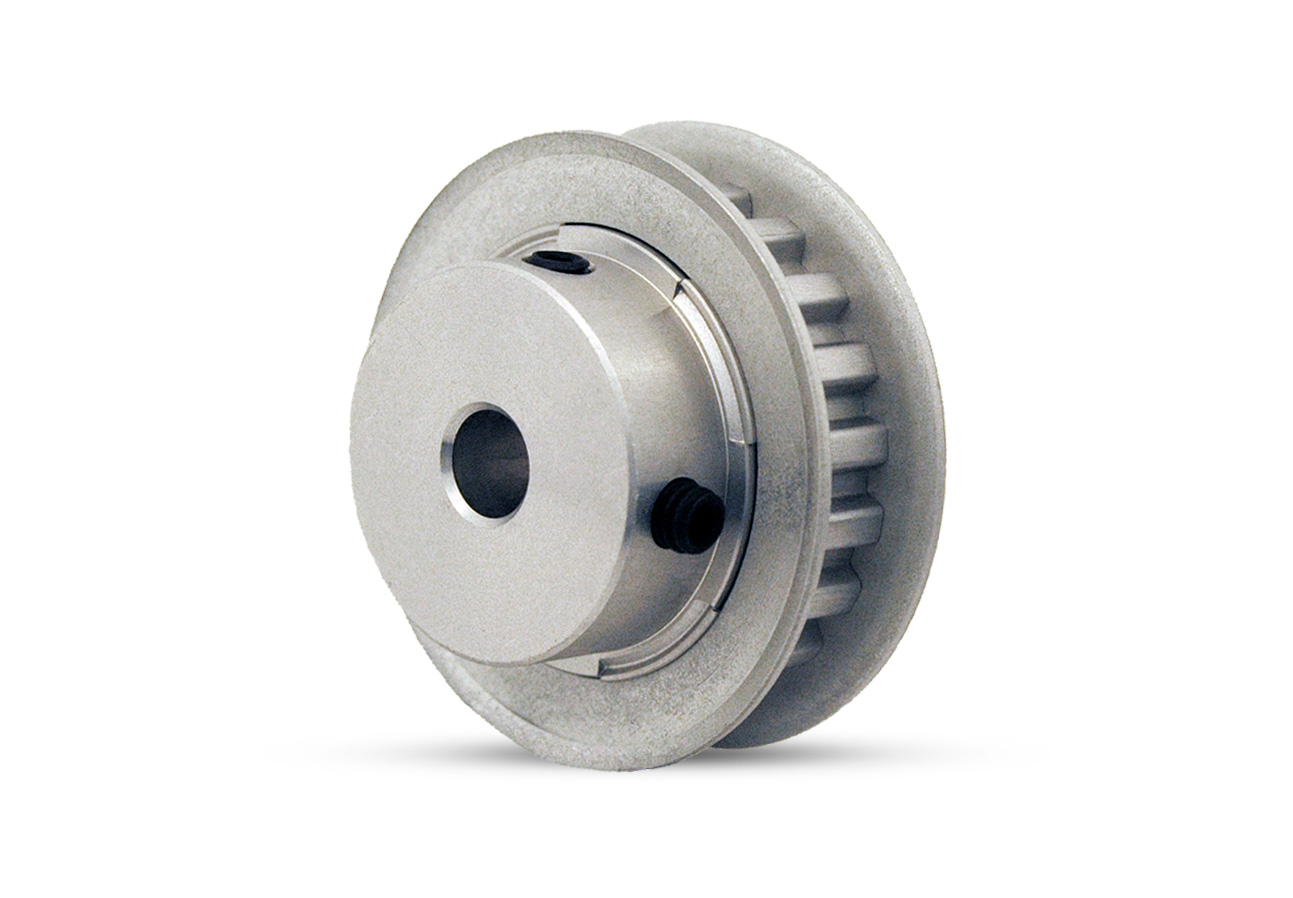

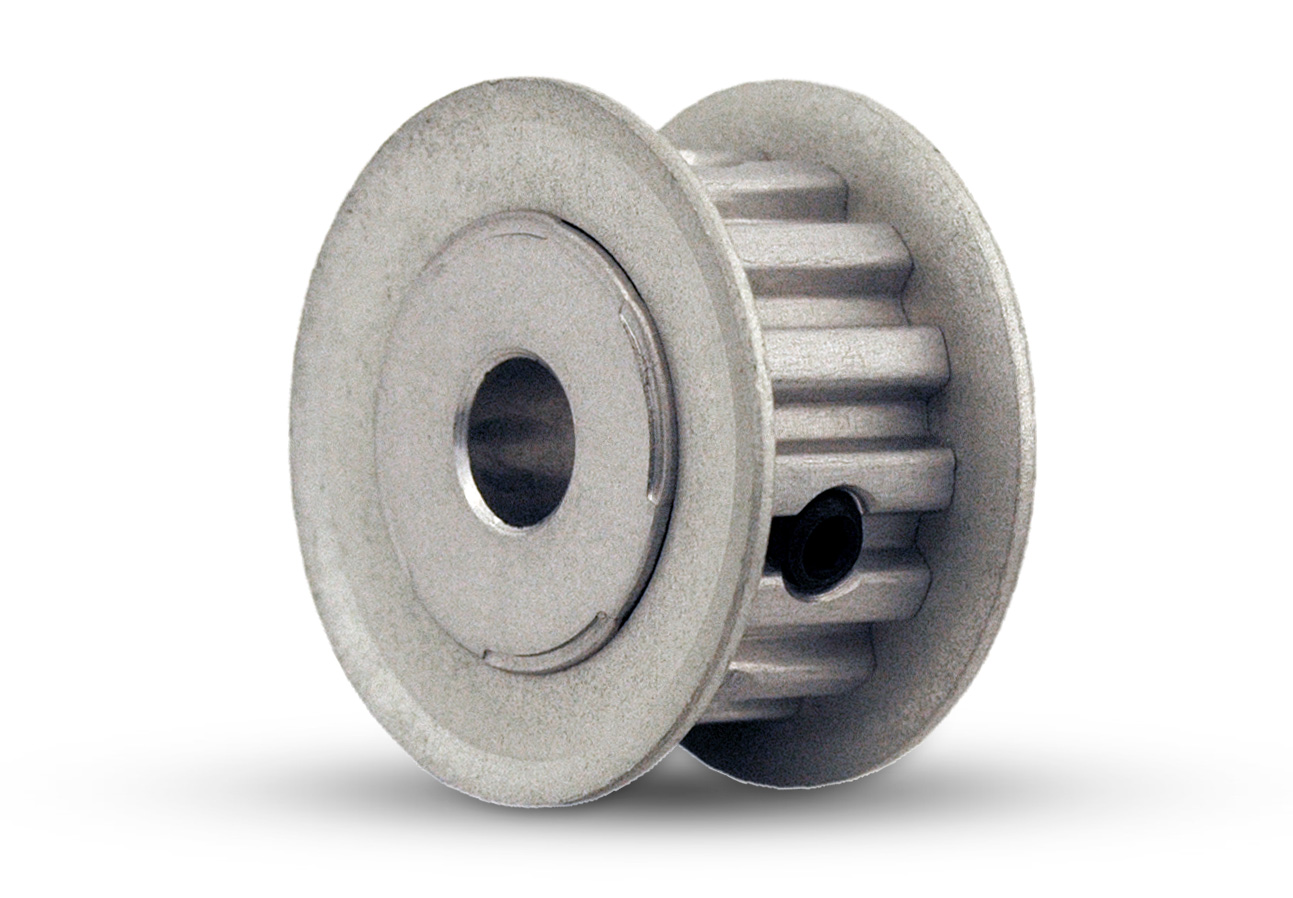

OEM Industrial Iron Transmission Timing Belt Pulleys with RoHS

Synchronous belt pulley transmission is composed of an annular belt with equidistant teeth on the inner peripheral surface and a belt pulley with corresponding teeth. During operation, the belt teeth mesh with the tooth slots of the belt pulley to transmit motion and power. It is a new belt transmission that integrates the respective advantages of belt transmission, chain transmission and gear transmission.

Product Parameters

| Product | standard timing belt pulley & idler pulley |

| Customized | OEM, drawings or samples customized |

| Teeth type | Normal Torque Drive Type:MXL,XL,L,H,XH,XXH High Torque Drive Type:S2M,S3M,S5M,S8M,HTD2M,HTD3M,HTD5M,HTD8M,P2M,P3M,P5M,P8M High Precision Position Drive Type:2GT,3GT,5GT,8YU Light Load Drive Type:T5,T10,T20 Heavy Load Drive Type:AT5,AT10,AT20 |

| Basic shape | Type A,Type B,Type D,Type E,Type F,Type K |

| Adaption | Adapt to 1/4 inch,5/16 inch,1/2 inch, 3/8inch, 2/25inch, 1/5inch belt |

| surface treatment | Natural color anodizing,Black anodizing,Hard anodizing,Ni-plating,Blackening |

| Material | 6061(aluminum),S45C(45# steel),SUS304(Stainless steel) |

| Bore | Pilot bore, Taper bore and Customized bore. |

| Tolerance Control | Outer diameter ±0.005mm Length dimension ±0.05mm |

| Standard | DIN, ISO/GB, AGMA, JIS |

| Teeth Accuracy | DIN Class 4, ISO/GB Classs 4, AGMA Class 13, JIS Class 0 |

| Weight | Max 15Tons |

| testing equipment | projecting apparatus,salt spray test,durometer,and coating thickness tester,2D projector |

| producing equipment | CNC machine,automatic lathe machine,stamping machine,CNC milling machine,rolling machine,lasering,tag grinding machine etc. |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching,Gear Shaving, Gear Grinding and Gear Lapping |

| Application industry | Robot industry,Medical industry,Making machine industry,Automation industry,3C industry equipment,Packaging industry,UAV industry,New energy industry. |

Company Profile

Packaging & Shipping

| lead time | 10-15 working days as usual,30days in busy season,it will based on the detailed order quantity |

| Delivery of samples | by DHL,Fedex,UPS,TNT,EMS |

FAQ

| Main markets | Southeast Asia, North America, Eastern Europe, Mid-East, West Europe |

| How to order | *You send us drawing or sample |

| *We carry through project assessment | |

| *We give you our design for your confirmation | |

| *We make the sample and send it to you after you confirmed our design | |

| *You confirm the sample then place an order and pay us 30% deposit | |

| *We start producing | |

| *When the goods is done,you pay us the balance after you confirmed pictures or tracking numbers | |

| *Trade is done,thank you! |

| Certification: | ISO9001:2008 |

|---|---|

| Pulley Sizes: | Type A |

| Manufacturing Process: | Forging |

| Material: | Aluminium Alloy |

| Surface Treatment: | Polishing |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Automation Equipment |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can XL pulleys be customized or modified for specific industrial needs?

Yes, XL pulleys can be customized or modified to meet specific industrial needs. Here’s a detailed explanation of how XL pulleys can be tailored for specific requirements:

1. Size and Configuration:

XL pulleys can be customized in terms of size and configuration to match the requirements of different industrial applications. The diameter, width, and overall dimensions of the pulleys can be adjusted to accommodate specific belt sizes, space constraints, or desired power transmission ratios. Customization in size and configuration ensures optimal fit and performance within the given system.

2. Material Selection:

The choice of materials for XL pulleys can be customized based on the operating conditions and environmental factors of an industrial application. For example, if the pulleys will be exposed to corrosive chemicals, materials with high corrosion resistance, such as stainless steel or specialized coatings, can be selected. Customized material selection ensures the pulleys can withstand the specific demands of the application.

3. Surface Coatings and Treatments:

To enhance the performance and longevity of XL pulleys, various surface coatings and treatments can be applied. These include coatings for improved wear resistance, low friction coatings to reduce energy loss, or specialized treatments for better grip or bonding with the timing belt. Customized surface coatings and treatments allow for specific performance enhancements based on the industrial needs.

4. Timing Belt Compatibility:

XL pulleys can be customized to ensure compatibility with specific types of timing belts. This involves designing the pulley’s tooth profile, pitch, and tooth spacing to match the corresponding timing belt’s specifications. Customization in timing belt compatibility ensures optimal engagement between the pulleys and belts, resulting in efficient power transmission and reduced wear.

5. Specialty Features:

XL pulleys can be customized with specialty features to address unique industrial needs. These features may include integrated flanges for belt tracking, keyways or set screw holes for secure shaft attachment, custom hub configurations for easy mounting, or special profiles to accommodate additional accessories or components. Specialty features provide added functionality and convenience in specific industrial applications.

6. Performance Optimization:

By understanding the specific requirements of an industrial application, XL pulleys can be customized to optimize their performance. This may involve modifying the pulley’s geometry, tooth profile, or tooth count to achieve desired torque transmission, speed ratios, or power requirements. Performance optimization ensures efficient operation and reliable performance in the intended application.

The ability to customize or modify XL pulleys for specific industrial needs allows for tailored solutions that meet unique requirements. Manufacturers or designers work closely with customers to understand their application demands and provide customized pulleys that deliver optimal performance, reliability, and efficiency.

How do advancements in material technology influence the design of modern XL pulleys?

Advancements in material technology have a significant impact on the design of modern XL pulleys. Here’s a detailed explanation of how these advancements influence their design:

1. Enhanced Durability:

New materials with improved strength and durability allow for the design of XL pulleys that can withstand higher loads, operate at higher speeds, and have increased resistance to wear and fatigue. Advanced materials, such as high-strength alloys, composites, or specialized polymers, provide superior mechanical properties, enabling the design of more robust and long-lasting pulleys.

2. Weight Reduction:

Lightweight materials, such as carbon fiber composites or engineered polymers, contribute to the design of lightweight XL pulleys. Reduced weight in pulley systems offers advantages such as improved energy efficiency, reduced inertia, and lower overall system weight. This is particularly beneficial in applications where weight reduction is critical, such as aerospace, automotive, or portable machinery.

3. Corrosion Resistance:

New materials with excellent corrosion resistance properties, such as stainless steel or corrosion-resistant coatings, enable the design of XL pulleys suitable for harsh or corrosive environments. Corrosion-resistant pulleys are essential in industries such as marine, chemical processing, or outdoor applications where exposure to moisture, chemicals, or saltwater can cause degradation and premature failure.

4. Temperature Resistance:

Advancements in material technology have led to the development of materials that can withstand extreme temperatures. For applications involving high or low temperature environments, such as industrial ovens, furnaces, or cryogenic systems, the use of materials with superior temperature resistance ensures the pulleys maintain their performance and integrity under challenging operating conditions.

5. Noise and Vibration Damping:

New materials with inherent damping properties, such as elastomers or composite laminates, contribute to the design of XL pulleys that can effectively reduce noise and vibrations during operation. This is particularly important in applications that require low noise levels or where excessive vibrations can affect the performance and reliability of the system.

6. Customization and Flexibility:

Advancements in material technology provide designers with a wider range of options to tailor the properties of XL pulleys to specific application requirements. Materials can be formulated or engineered to meet specific needs such as high friction coefficients, electrical conductivity, or resistance to specific chemicals. This customization and flexibility in material selection allow for the optimization of pulley design and performance for various applications.

Overall, advancements in material technology have revolutionized the design of modern XL pulleys by offering improved durability, reduced weight, corrosion resistance, temperature resistance, noise and vibration damping, and customization options. Manufacturers can leverage these advancements to develop pulleys that meet the evolving needs of diverse industries and deliver enhanced performance and reliability.

In which applications and industries are XL pulleys commonly used?

XL pulleys find extensive use in various applications and industries that require precise motion control and power transmission. Here are some common applications and industries where XL pulleys are commonly employed:

1. Robotics:

XL pulleys are utilized in robotic systems for precise positioning and movement control of robot arms, grippers, and other robotic components. They enable accurate and synchronized motion, allowing robots to perform complex tasks with precision.

2. CNC Machines:

CNC (Computer Numerical Control) machines, such as milling machines and lathes, rely on XL pulleys for precise control of spindle speed and tool positioning. The accurate motion provided by XL pulleys ensures high-quality machining and dimensional accuracy in CNC operations.

3. 3D Printers:

XL pulleys are commonly used in 3D printers to control the movement of the print head and the positioning of the build platform. The precise motion control facilitated by XL pulleys contributes to the accuracy and fine detail of the printed objects.

4. Automated Systems:

XL pulleys are employed in various automated systems, including conveyor systems, packaging machinery, assembly lines, and material handling equipment. These systems require synchronized and precise motion to ensure efficient and accurate operation.

5. Industrial Machinery:

In industrial settings, XL pulleys are used in a wide range of machinery, such as textile machines, printing presses, woodworking equipment, and industrial automation systems. They provide reliable power transmission and motion control in these demanding applications.

6. Automotive Industry:

XL pulleys are utilized in automotive applications, including engine timing systems, accessory drives, and power steering systems. The precise control and synchronization offered by XL pulleys contribute to efficient and reliable operation of these automotive components.

7. Medical Devices:

In the medical field, XL pulleys are found in equipment such as diagnostic machines, laboratory automation systems, and surgical instruments. They enable accurate movement and positioning, ensuring the precision required for medical procedures and diagnostics.

8. Aerospace and Defense:

XL pulleys are used in aerospace and defense applications, such as satellite positioning systems, guidance systems, and unmanned aerial vehicles (UAVs). The reliable motion control provided by XL pulleys is crucial for the accurate operation of these aerospace and defense systems.

9. Research and Development:

In research and development laboratories, XL pulleys are employed in experimental setups, prototyping systems, and testing equipment. Their precise motion control capabilities support the development and validation of new technologies and products.

In summary, XL pulleys are commonly used in applications and industries that require precise motion control and power transmission. Their versatility and reliability make them suitable for a wide range of applications, from robotics and CNC machines to 3D printers, automated systems, automotive components, medical devices, aerospace, and research and development.

editor by CX

2023-11-13