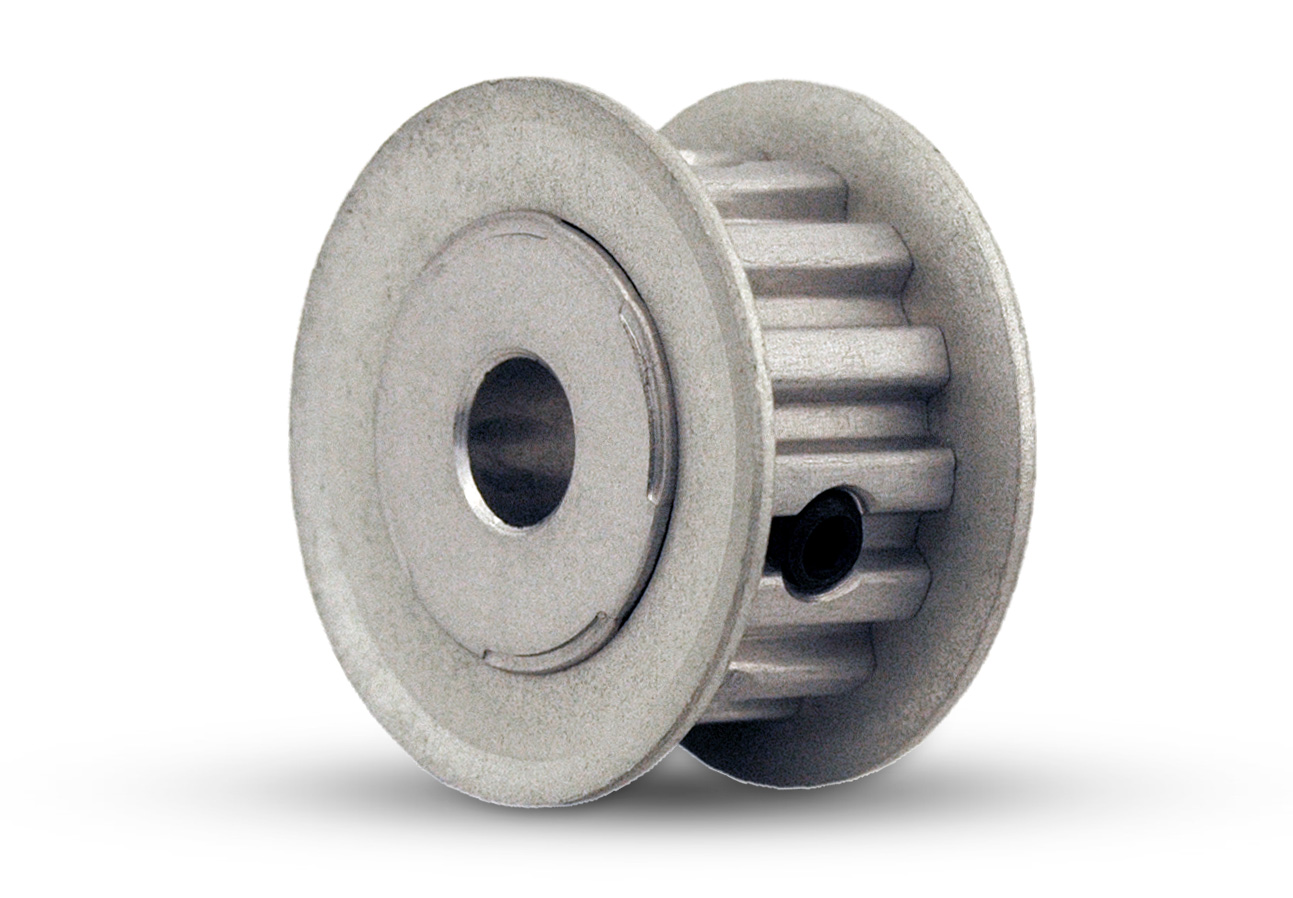

Product Description

NEED TO KNOW BEFORE BUYING

Thank you for browsing our product.

All our product can be customized as per your request or as per your drawings, please feel freel to contact us any time by e-Mail for quicker respond to your inquiry.

CHINAMFG Industrial Belt Co., Ltd, is a leading manufacturer of high quality industrial belts and pulleys that are used in many various types of machinery.

We are a supplier of well known Asian manufacturers, like Media, Lesso, and others. We’re based in HangZhou City, ZheJiang Province, which is known for being a Business Incubator for high-tech industrial chains.

We regularly keep most commonly used items in stock, so we don’t have problems with filling small quantity orders.

For custom made parts, our production lead time is 3 to 30 days, depending on the raw material stock availability and the complexity of the customized items.

Apart from our own CHINAMFG brand, we also supply OEM for many well known brands during CHINAMFG seasons.

Our materials are supplied through leading enterprises in the industry, and we work closely with them to guarantee our products’ quality. As a result, the majority of our clients do remain in long term business relationships with us.

Like many Chinese factories, CHINAMFG is aiming at direct sales to international markets, and we are adding more afer sales service personnel to meet the growing needs of our clients.

Direct Sales provides mutual benefits, including cutting the cost to our overseas clients, and expanding our business into the future.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Pulley Sizes: | Customized as Per Request |

|---|---|

| Manufacturing Process: | CNC, Casting |

| Material: | Aluminum, Casting, Stainless Steel |

| Surface Treatment: | Oxygenation |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant, Industrial Machinery |

| Delivery Time: | 7-10days |

| Customization: |

Available

| Customized Request |

|---|

What is the significance of precision machining in XL pulley manufacturing?

Precision machining plays a crucial role in XL pulley manufacturing, offering several significant benefits. Here is a detailed explanation of the significance of precision machining in XL pulley manufacturing:

1. Accurate Dimensional Control:

Precision machining ensures accurate dimensional control in the manufacturing process of XL pulleys. The precise shaping and machining of the pulleys’ components, such as the hub, bore, and tooth profile, guarantee the correct fit and alignment with other components in the power transmission system. Accurate dimensional control results in smooth and efficient operation of the pulleys.

2. Consistent Tooth Profile:

Precision machining allows for the consistent production of the tooth profile on XL pulleys. The teeth on the pulleys must have precise shapes and dimensions to properly engage with the teeth of the timing belt, ensuring reliable power transmission. Consistency in tooth profile eliminates irregularities or variations that could lead to belt slippage, premature wear, or reduced system efficiency.

3. High Surface Quality:

Precision machining techniques produce XL pulleys with high surface quality. The smooth and polished surfaces of the pulleys reduce friction and wear, contributing to improved efficiency and prolonged belt life. High surface quality also minimizes noise, vibrations, and the risk of debris accumulation, ensuring smooth and reliable operation in various industrial applications.

4. Tight Tolerances:

Precision machining allows for the production of XL pulleys with tight tolerances. Tight tolerances ensure close adherence to specified dimensions and performance requirements. The precise alignment of pulley components, such as the bore and keyway, with the shaft guarantees a secure and accurate fit. Tight tolerances enhance the pulley’s overall performance, reliability, and compatibility with other system components.

5. Customization Capabilities:

Precision machining enables the customization of XL pulleys to meet specific application requirements. Manufacturers can easily modify the pulley’s design, dimensions, or features to tailor it for unique industrial needs. Precision machining techniques facilitate the production of custom pulleys with precise specifications, ensuring optimal performance and compatibility with the intended application.

6. Efficient Production Process:

Precision machining techniques, such as computer numerical control (CNC) machining, offer efficient and automated processes for XL pulley manufacturing. CNC machines can produce pulleys with high accuracy and repeatability, reducing human errors and ensuring consistent quality. The efficient production process enabled by precision machining results in cost-effective manufacturing, shorter lead times, and increased production capacity.

In summary, precision machining is of significant importance in XL pulley manufacturing due to its ability to achieve accurate dimensional control, consistent tooth profile, high surface quality, tight tolerances, customization capabilities, and efficient production processes. These factors contribute to the overall performance, reliability, and compatibility of XL pulleys in various industrial applications.

What maintenance practices should be followed to ensure the longevity of XL pulleys?

To ensure the longevity of XL pulleys, it is important to follow proper maintenance practices. Here are some key practices to consider:

1. Regular Inspection:

Perform regular visual inspections of the XL pulleys to check for any signs of wear, damage, or misalignment. Look for worn-out or damaged teeth, cracks, or excessive wear on the pulley surfaces. Inspect the pulleys for proper alignment and ensure that they are securely mounted.

2. Belt Tension:

Maintain the proper tension in the timing belt that is used with the XL pulleys. Incorrect belt tension can cause slippage, premature wear, and reduced power transmission efficiency. Follow the manufacturer’s guidelines or specifications to determine the correct tension for the specific application and adjust it accordingly.

3. Lubrication:

XL pulleys typically do not require lubrication as they are designed for dry operation. However, in some cases, the manufacturer may recommend specific lubrication practices for certain applications. If lubrication is required, use the recommended lubricant and follow the manufacturer’s instructions carefully.

4. Cleaning:

Keep the XL pulleys clean and free from debris, dust, or other contaminants. Regularly clean the pulleys using a soft brush or cloth to remove any build-up that may affect their performance or cause premature wear.

5. Environmental Considerations:

Consider the operating environment of the XL pulleys and take appropriate measures to protect them. In harsh or corrosive environments, use pulleys made from materials that are resistant to corrosion or degradation. Implement protective measures such as covers or enclosures to shield the pulleys from exposure to dirt, moisture, or chemicals.

6. Replacement:

If any signs of significant wear, damage, or deformation are observed during inspections, consider replacing the XL pulleys promptly. Continuing to use worn-out or damaged pulleys can lead to reduced performance, increased risk of failure, and potential damage to other components in the power transmission system.

It is important to consult the manufacturer’s guidelines and recommendations for specific maintenance practices for the XL pulleys used in your application. Following the recommended maintenance practices will help ensure the longevity, reliability, and optimal performance of the XL pulleys in power transmission systems.

In which applications and industries are XL pulleys commonly used?

XL pulleys find extensive use in various applications and industries that require precise motion control and power transmission. Here are some common applications and industries where XL pulleys are commonly employed:

1. Robotics:

XL pulleys are utilized in robotic systems for precise positioning and movement control of robot arms, grippers, and other robotic components. They enable accurate and synchronized motion, allowing robots to perform complex tasks with precision.

2. CNC Machines:

CNC (Computer Numerical Control) machines, such as milling machines and lathes, rely on XL pulleys for precise control of spindle speed and tool positioning. The accurate motion provided by XL pulleys ensures high-quality machining and dimensional accuracy in CNC operations.

3. 3D Printers:

XL pulleys are commonly used in 3D printers to control the movement of the print head and the positioning of the build platform. The precise motion control facilitated by XL pulleys contributes to the accuracy and fine detail of the printed objects.

4. Automated Systems:

XL pulleys are employed in various automated systems, including conveyor systems, packaging machinery, assembly lines, and material handling equipment. These systems require synchronized and precise motion to ensure efficient and accurate operation.

5. Industrial Machinery:

In industrial settings, XL pulleys are used in a wide range of machinery, such as textile machines, printing presses, woodworking equipment, and industrial automation systems. They provide reliable power transmission and motion control in these demanding applications.

6. Automotive Industry:

XL pulleys are utilized in automotive applications, including engine timing systems, accessory drives, and power steering systems. The precise control and synchronization offered by XL pulleys contribute to efficient and reliable operation of these automotive components.

7. Medical Devices:

In the medical field, XL pulleys are found in equipment such as diagnostic machines, laboratory automation systems, and surgical instruments. They enable accurate movement and positioning, ensuring the precision required for medical procedures and diagnostics.

8. Aerospace and Defense:

XL pulleys are used in aerospace and defense applications, such as satellite positioning systems, guidance systems, and unmanned aerial vehicles (UAVs). The reliable motion control provided by XL pulleys is crucial for the accurate operation of these aerospace and defense systems.

9. Research and Development:

In research and development laboratories, XL pulleys are employed in experimental setups, prototyping systems, and testing equipment. Their precise motion control capabilities support the development and validation of new technologies and products.

In summary, XL pulleys are commonly used in applications and industries that require precise motion control and power transmission. Their versatility and reliability make them suitable for a wide range of applications, from robotics and CNC machines to 3D printers, automated systems, automotive components, medical devices, aerospace, and research and development.

editor by CX

2024-04-25