Product Description

| Model NO. | Custom Parts | Application | Fastener, Auto and Motorcycle Accessories, Hardware Tool, Machinery Accessory |

| Standard | GB, EN, China GB Code, JIS Code, TEMA, ASME | Surface Treatment | Anodizing |

| Production Type | Mass Production | Machining Method | CNC Machining |

| Material | Nylon, Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron | Drawing Type | Dwg, Dxf, Step, Iges, Pdf, STP, etc. |

| Tolerance | +/-0.002mm, or Customized | Roughness | Ra0.2-Ra3.2 , or Customized |

| Surface Finish | Anodization, Plating, Passivation, Polish, Brush | Colors | Blue, Red, Black, Gold, Orange, Green, Gray, White |

| Sample Service | Available | Part Name | CNC Machining Parts |

| Service | Machining, Assembly, Surface Treatment, etc. | Dimensions | Customized |

| Lead Time | 1-4 Weeks Depends on Requests | MOQ | 1 PCS, But Over 100PCS Is a Price Break Point |

| Machining Capability | 3,4,5 Axis CNC Milling, CNC Turning, Sheet Metal | Price | Negotiable as Per Request |

| Transport Package | Foam, Carton | Specification | Custom dimension |

| Trademark | Custom | Origin | China |

| HS Code | 84799 0571 0 | Production Capacity | 50000PCS |

Product Description

| Parts Application | Industrial Parts, Bikes, Engine parts, Robotic Parts, Decoration, BMX, EDC, yoyo, CHINAMFG parts, Electronics aluminum parts, Toys parts, Gears, Car parts, 4X4 parts, Medical Parts. Oil industry parts. Audio equipment parts, Musical Instrument parts |

||

| Machining Tolerance | The best tolerance is +/-0.002mm, can do as per your request. | ||

| Roughness | Ra0.2-Ra3.2, (as per specification) | ||

| Quotation | Need to know material, quantity, surface treatment, and another special request before sending you a quotation | ||

| Software Available | CAD, CHINAMFG Works, UG, CAD/CAM/CAE, PDF. | ||

| Surface Finish | Matte, Glossy, Tumbling, Smooth, beadblasting. | ||

| Surface Treatment | Anodization, Plating, Passivation, Polishing, Brushing. | ||

| Materials Available | Aluminum, Brass, Copper, Stainless Steel, Titanium, PVC, ABS, PEEK, Nylon, Delrin, Acrylic, Steel | ||

| Inspection instruments | Height Gauge, CMM, Caliper, Electronics Scale, Micrometer/Microcaliper, Gage Blocks, Pin Gauge. | ||

| Service Available | 1. CNC machining, CNC milling, CNC turning, Sheet Metal, Laser cutting, 2. Assemble (Using press fit or other technology), 3. Packing for “ready to sale” products, 4. Customized Packaging, 5. Relative accessory purchasing. |

||

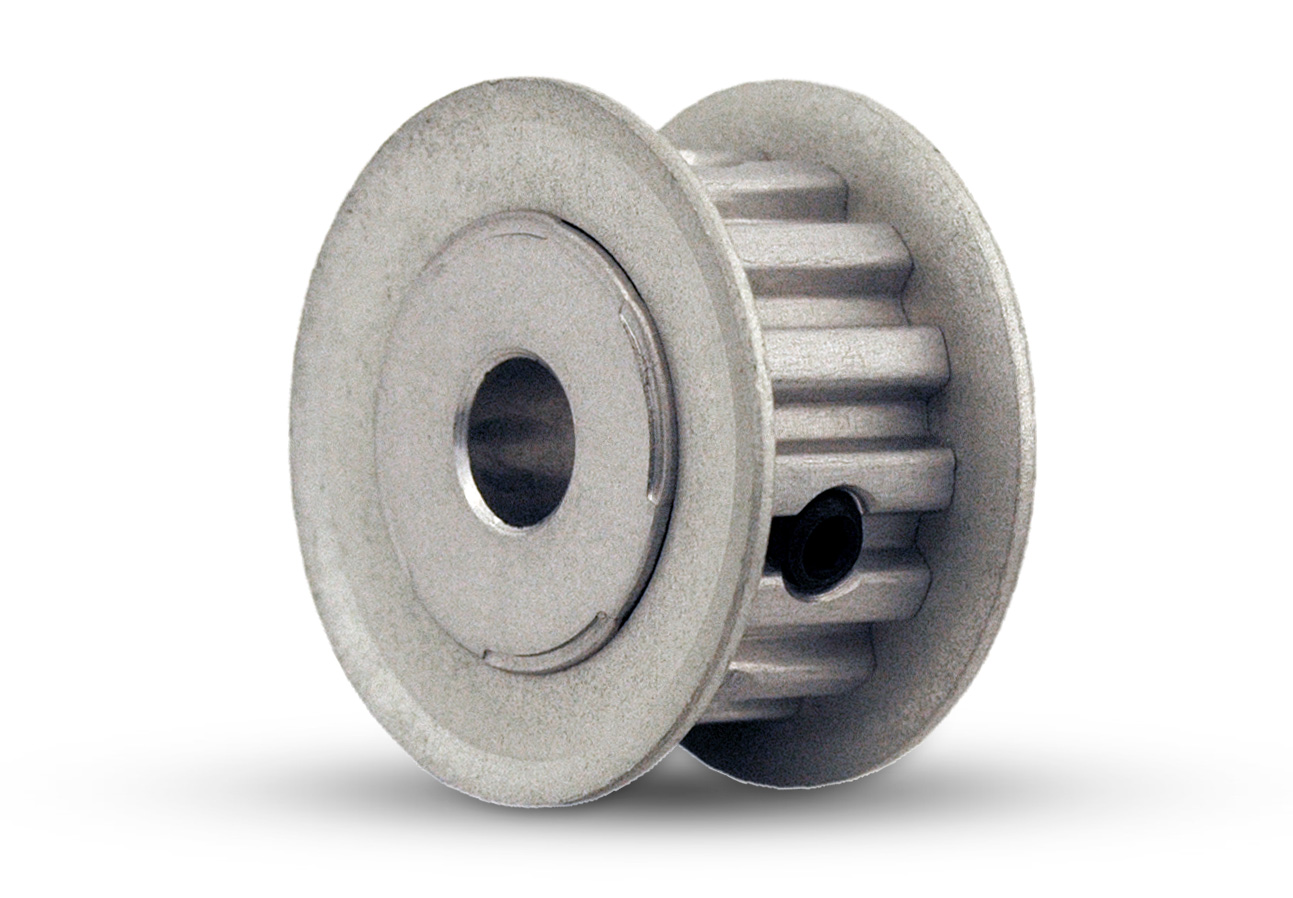

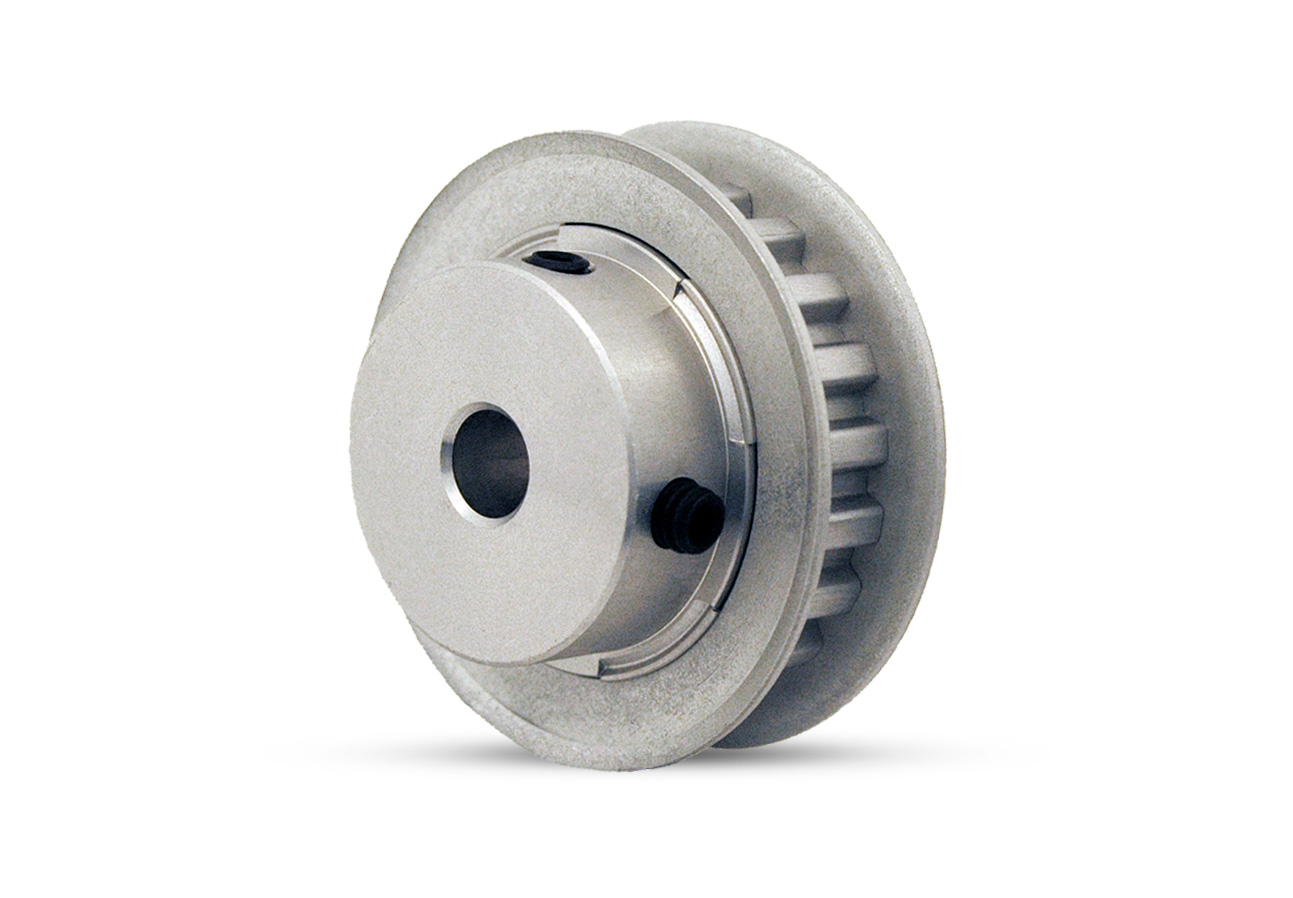

Sample Parts Show

Why Choose us

Our Equipments

Test Report Sample

Certifications

Our Package

FAQ

| Q1. Are you a genuine manufacturer? | |||

| Yes, all the products are produced in our ISO9001:2015 certified factory; We are also a company registered by China Customs with the right to export and import. | |||

| Q2. What should I offer to get your quotation? | |||

| Please offer us your detailed information for the product, such as drawings with 2D/3D by software Pro/E, Auto CAD, SolidWorks, UG etc; as well as materials, surface treatment, quantity, package. Any special requirements should be highlighted especially for tolerance. | |||

| Q3. Can we get a complete product besides CNC parts? | |||

| To some extent, yes, we can. But firstly we need assess feasibility. | |||

| Q4. What’s your top process tolerance? | |||

| Now our top process tolerance is ± 0.005mm. | |||

| Q5. What are your sample policy and trade/payment terms? | |||

| We can offer the free samples with total value less than USD10; while the buyers should bear shipping cost and import VAT. | |||

| Ex-works, FOB ZheJiang /HangZhou, CIF etc. would be OK for us. | |||

| As for the payment, small value is recommended by Paypal or Western Union; larger amount by T/T, 50% as deposit, 50% before shipment. | |||

| Q6. How about the warranty? | |||

| The warranty is for 1 year. As you know, our CNC parts have a long lifespan except for damaged by operating inappropriately. | |||

| Q7. What’s your policy for RMA? | |||

| All defective products should be confirmed by us based on the customers’ RMA list and photos first, then we’d like to refund the money or compensate the goods by free of charge accordingly. | |||

| Q8. I want to keep our design in confidence; can we CHINAMFG NDA? | |||

| Sure, to protect customers’ profit is our obligatory responsibility, signed NDA would be valid to both of us. | |||

| . | |||

| What benefit we can get from you? | |||

| 1) Competitive price | |||

| 2) High quality control : 100% full inspection before shipment | |||

| 3) High precision, tolerance can be ± 0.005mm | |||

| 4) Fast lead time (5-7days for samples, 12-15 days for mass production) | |||

| 5) Non-standard//OEM//customized service provided | |||

| 6) No MOQ, small QTY is acceptable. | |||

| 7) Factory ISO 9001 certification, ROHS material used | |||

| 9) Professional export packing: separate Blister plastic box or Bubble Wrap/Pearl Wool +Carton+ Wooden Case, keep no scratch and damage |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard: | GB |

|---|---|

| Surface Treatment: | Anodizing, Painting, Phosphating, Passivation… |

| Customization: | Yes |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What environmental factors should be considered when using XL pulleys outdoors?

When using XL pulleys outdoors, several environmental factors should be taken into consideration. Here is a detailed explanation of the factors that should be considered:

1. Moisture and Water Exposure:

Outdoor environments often expose XL pulleys to moisture and water, such as rain, humidity, or even direct water contact. It is crucial to consider the pulleys’ resistance to corrosion and rust in such conditions. Choosing pulleys made from materials with high corrosion resistance, such as stainless steel or coated alloys, can help prevent damage and ensure long-term performance.

2. Temperature Variations:

Outdoor environments may subject XL pulleys to temperature variations, including extreme heat or cold. Different materials exhibit varying thermal properties, so selecting pulleys with suitable temperature resistance is essential. Pulleys made from materials that can withstand the anticipated temperature range will help prevent deformation, cracking, or premature wear due to thermal expansion or contraction.

3. UV Radiation:

XL pulleys used outdoors are exposed to ultraviolet (UV) radiation from sunlight. Prolonged exposure to UV radiation can cause material degradation, discoloration, or loss of mechanical properties. Choosing pulleys with UV-resistant coatings or materials that are specifically formulated to withstand UV radiation can mitigate these effects and ensure the longevity and performance of the pulleys.

4. Dust and Particulate Matter:

Outdoor environments often contain dust, dirt, and other particulate matter that can accumulate on XL pulleys. The presence of debris can lead to increased friction, wear, and decreased performance. Choosing pulleys with smooth surfaces, effective seals, or protective covers can help minimize the ingress of dust and particulate matter, reducing the risk of damage and maintaining optimal operation.

5. Chemical Exposure:

In certain outdoor applications, XL pulleys may come into contact with chemicals, such as solvents, cleaning agents, or environmental pollutants. It is crucial to consider the chemical compatibility of the pulley materials with the substances present in the environment. Selecting pulleys made from chemically resistant materials or applying protective coatings can prevent chemical reactions, degradation, or premature failure.

6. Vibrations and Mechanical Stresses:

Outdoor environments may subject XL pulleys to vibrations and mechanical stresses caused by factors like wind, machinery vibrations, or uneven terrain. It is important to ensure that the pulleys are designed and installed to withstand these forces. Reinforcing the pulleys with appropriate structural features, such as additional ribs or thicker walls, can enhance their durability and prevent mechanical failures.

7. Maintenance and Inspection:

Outdoor XL pulleys may require more frequent maintenance and inspection compared to indoor applications. Regular cleaning, lubrication, and inspection of the pulleys can help identify and address any environmental damage or wear in a timely manner. Implementing a maintenance schedule and following manufacturer-recommended guidelines will ensure the pulleys remain in optimal condition.

By considering these environmental factors when using XL pulleys outdoors, it is possible to select pulleys that are specifically designed and constructed to withstand the challenges posed by the outdoor environment. This ensures reliable performance, longevity, and minimal downtime in outdoor applications.

Are there safety considerations when working with XL pulley systems?

Yes, there are several safety considerations that should be taken into account when working with XL pulley systems. Here are some important safety considerations:

1. Lockout/Tagout Procedures:

Before performing any maintenance or repair tasks on a power transmission system involving XL pulleys, it is crucial to follow proper lockout/tagout procedures. This involves isolating the system from its power source and ensuring that it cannot be energized accidentally. Lockout/tagout procedures help prevent unexpected startup of the system, which could cause serious injuries.

2. Personal Protective Equipment (PPE):

Wear appropriate personal protective equipment when working with XL pulley systems. Depending on the specific task and potential hazards, PPE may include safety glasses, gloves, hearing protection, and protective clothing. PPE helps protect against potential injuries from contact with moving parts, flying debris, or noise exposure.

3. Training and Competence:

Ensure that personnel working with XL pulley systems are adequately trained and competent to perform their tasks safely. They should be familiar with the proper procedures for installation, operation, and maintenance of the pulleys. Training should also cover the identification and understanding of potential hazards associated with the system and how to mitigate them.

4. Machine Guards:

Install appropriate machine guards and protective enclosures around the XL pulley systems to prevent accidental contact with moving parts. Guards help minimize the risk of entanglement, pinch points, or injuries caused by the rotating pulleys or the timing belt.

5. Risk Assessment:

Conduct a thorough risk assessment of the XL pulley system and its surrounding environment. Identify and evaluate potential hazards, such as pinch points, sharp edges, or electrical hazards. Implement control measures to mitigate the identified risks, such as implementing interlocks, providing warning signs, or establishing safe work procedures.

6. Regular Maintenance:

Perform regular maintenance and inspection of the XL pulley system to ensure its safe operation. This includes checking for any signs of wear, damage, or misalignment, as well as verifying the integrity of guards and safety devices. Address any maintenance issues promptly to prevent potential safety hazards.

It is important to consult relevant safety standards, guidelines, and regulations specific to your industry and jurisdiction when working with XL pulley systems. Adhering to these safety considerations will help protect personnel from injuries and create a safe working environment when interacting with XL pulley systems.

How do XL pulleys enhance the precision and efficiency of mechanical systems?

XL pulleys play a crucial role in enhancing the precision and efficiency of mechanical systems by providing precise motion control and efficient power transmission. Here are the key ways in which XL pulleys contribute to the improvement of mechanical systems:

1. Accurate Motion Control:

XL pulleys, when used in conjunction with timing belts, enable accurate and synchronized motion control. The tooth profile of XL pulleys is designed to match the tooth profile of the timing belt, ensuring precise engagement and motion transfer. This accuracy in motion control allows mechanical systems to achieve precise positioning, movement, and coordination of components.

2. Positioning Accuracy:

By providing precise motion control, XL pulleys contribute to positioning accuracy in mechanical systems. Whether it’s a robotic arm, a CNC machine tool, or a 3D printer, the precise movement enabled by XL pulleys ensures that components or tools are positioned with high accuracy, resulting in the desired output or product quality.

3. Repeatability:

XL pulleys facilitate consistent and repeatable motion in mechanical systems. The accurate engagement between the pulleys and timing belts ensures that the same motion is reproduced reliably each time. This repeatability is essential in applications where consistent results are required, such as in manufacturing processes or automated systems.

4. Reduced Backlash:

Backlash refers to the undesired clearance or play between mating components, which can cause inaccuracies and imprecise motion. XL pulleys, with their precise tooth engagement with timing belts, minimize backlash in mechanical systems. This reduction in backlash improves the overall precision and eliminates unwanted movement or positioning errors.

5. Efficiency in Power Transmission:

XL pulleys, when combined with properly sized timing belts, offer efficient power transmission in mechanical systems. The toothed nature of the pulleys and belts allows for high torque transfer, minimizing slippage and ensuring reliable power delivery. This efficiency in power transmission maximizes the utilization of energy and reduces energy losses, resulting in improved overall system efficiency.

6. Interchangeability and Flexibility:

XL pulleys adhere to standardized dimensions and tooth profiles, allowing for interchangeability between different manufacturers. This interchangeability provides flexibility in system design, maintenance, and upgrades. It also simplifies the replacement of pulleys, which can be beneficial in minimizing downtime and reducing costs.

7. Load Handling Capability:

XL pulleys are designed to handle moderate to high torque requirements. This load handling capability makes them suitable for various applications that require robust and reliable power transmission, such as in heavy machinery, automation systems, or industrial equipment.

By enhancing precision in motion control, improving efficiency in power transmission, and offering flexibility in system design, XL pulleys contribute to the overall performance and reliability of mechanical systems. They enable accurate positioning, repeatable motion, and efficient energy transfer, leading to improved productivity, quality, and operational efficiency.

editor by CX

2024-04-16